Horticultural Facility Design

Horticulture Process Engineering

We collaborate with clients, facility architecture, and building engineering teams on the full horticultural system design. With a full system view and perspective, we distill customer business objectives down to detailed design of a system to achieve those goals.

When designing an end to end Horticultural Process, we cover the following areas:

Overall Conditions of Satisfaction - What are you trying to achieve?

What are you trying to achieve with this cultivation project? Quality? Yield? Efficiency? A speciality in growing 12 week African cultivars? High end leafy greens, sprouts and herbs for high end restaurants? Is this a new or mature state market? Target base business margin? What are your sustainability goals? Target cost of production? Do you want to build this business to be sold to an MSO or handed down to your kids? Cultivars and techniques already pre-selected…Or Total blue sky? Organic living soil in no till beds?..or rockwool blocks pulse irrigated?

Through these initial discovery conversations we ensure the design holistically meets the business and brand goals. Everything we do starts here, and we develop all of the specs and technical implementations to be compatible with this narrative. Our design always refers back to these initial ‘conditions of satisfaction’. There is no ‘one size fits all’ solution (or even ‘one size fits most’).

Projections of yield and production cost to ensure business plan compatibility

With our experience across different cultivation strategies and the data we have collected on them, we can project a realistic range of yield expectations to inform your financial modeling and drive alignment with your stakeholders.

Forecasting farm output during early design phase based on ownership methodology

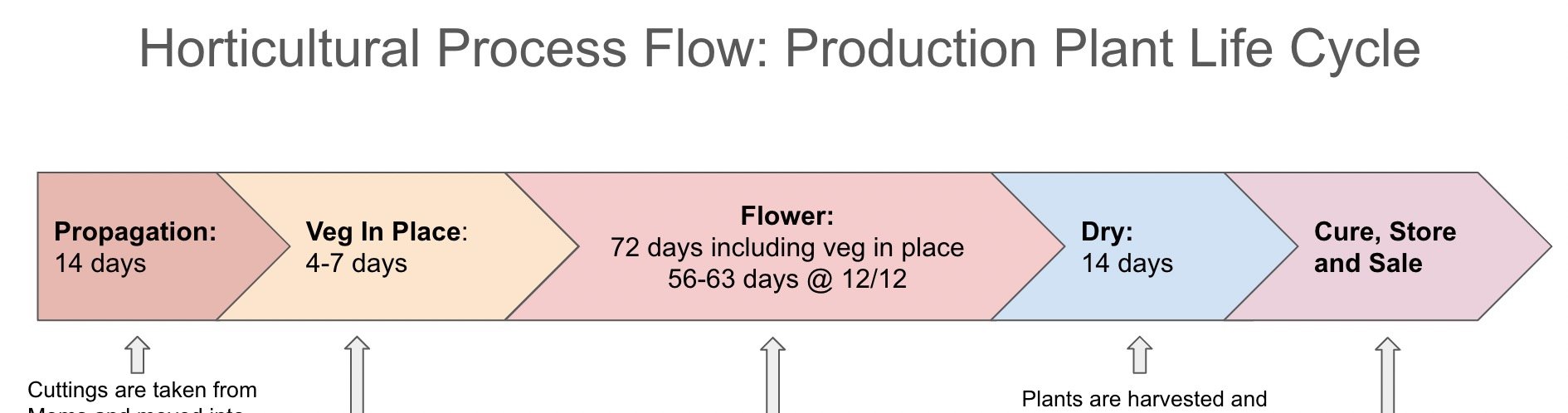

Plant Production Strategy and Process Flow

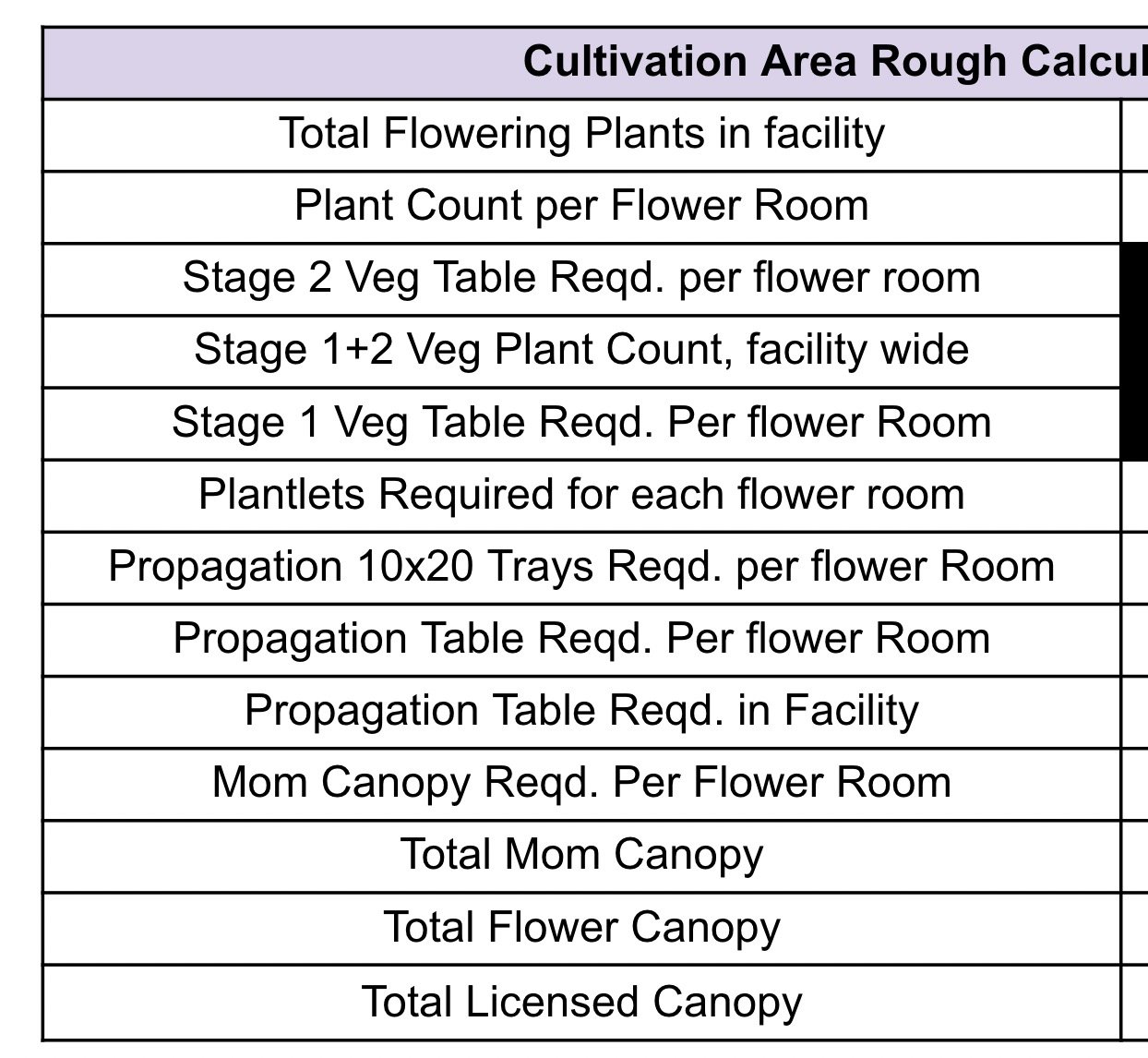

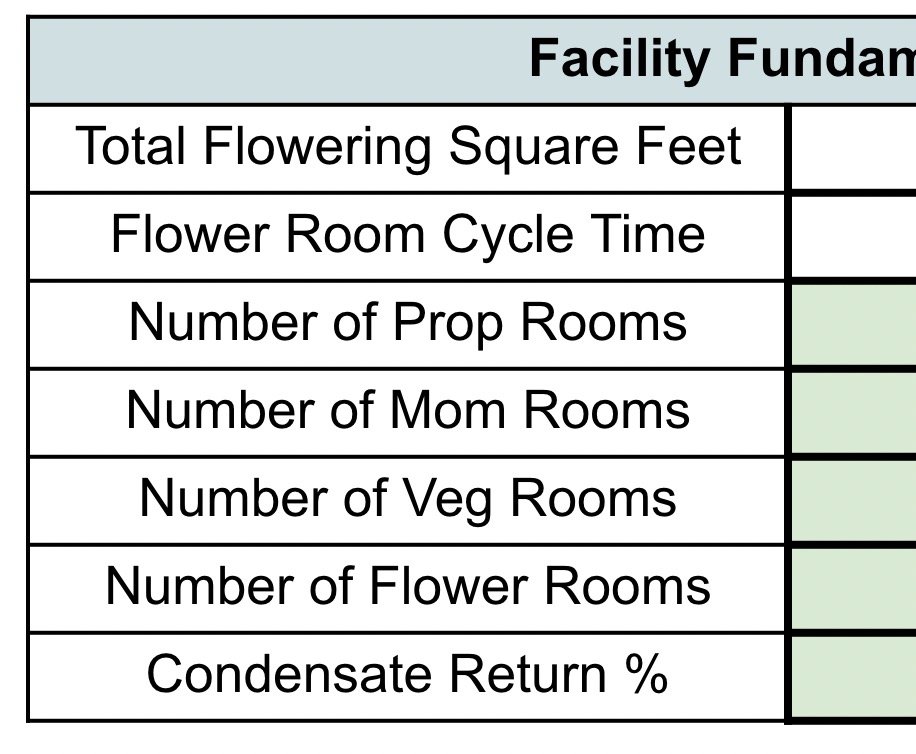

Part of developing a horticultural system is specifying a schedule and speed that plants move through the facility. We design versatility into these systems so schedules can be scaled up and back as needs change. Using our experience in designing traditional manufacturing and industrial processes, we apply a combination of lean manufacturing and cell manufacturing tactics to horticulture.

Well planned plant movement through the facility is critical to a smooth running operation.

Plant-Centric Design

A horticulture facility at its core is about the plants and the people maintaining them. If the design enables the plants to be happy, the staff will feel empowered and at ease, which will lead to happier plants and so on. In our view, when the plants and staff are working together well, favorable business outcomes follow.

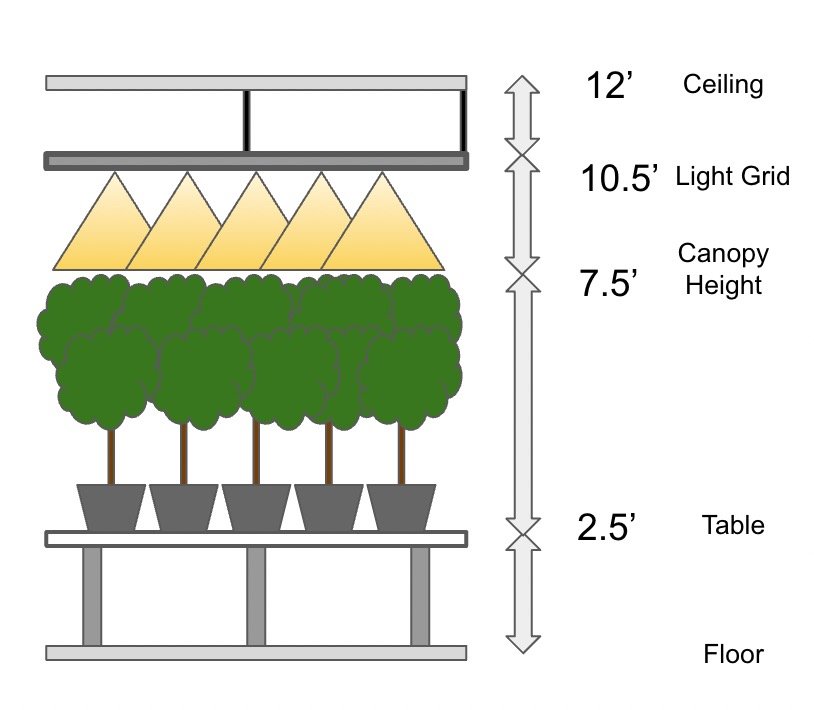

We evaluate your business narrative, look at the existing conditions (eg. the building, budget, schedule, etc.) and together select a plant strategy. To inform the rest of the building design, we select the floor layouts and elevations based on the size and stature of the plants you want to grow. We are technique agnostic: we have implemented flower production systems in single, double, triple and quad tier formats with a wide variety of root zone tactics (e.g. hydroponics, organics, aquaponics, aeroponics, NFT). These are all selected based on the particular context and the conditions of satisfaction laid out at project inception.

We design the facility around the plants, not the other way around

Each sub process encompasses its own set of variables, inputs and outputs

These are integrated systems - one change causes ripple effects through the rest of the farm design

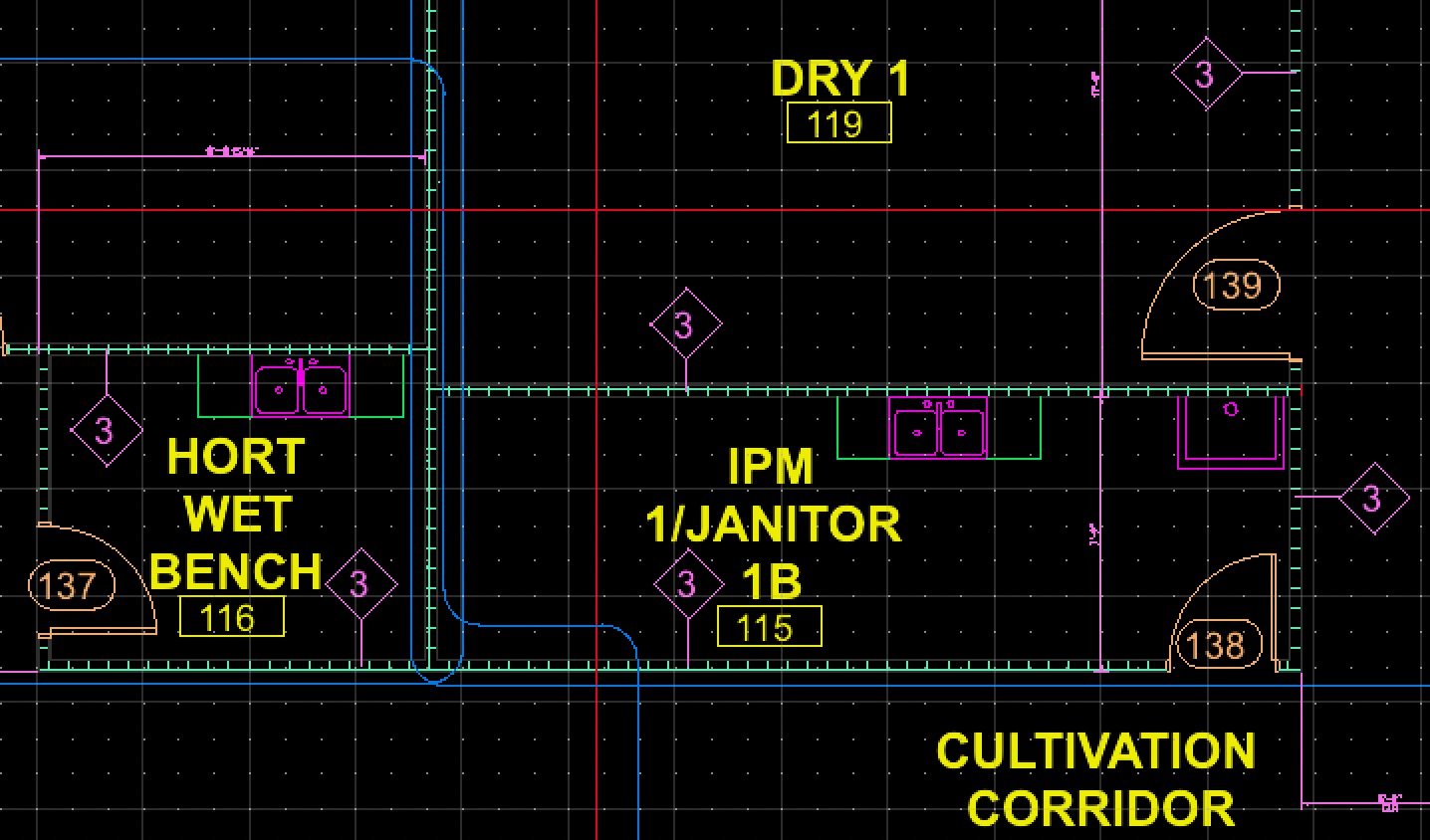

As facilities grow in size, there are several different room types each with their own functions, narrative, and interdependencies

Integration with Building Architecture and MEP Engineering

As the design project progresses, we give specifications and design guidelines to the architects and MEP Engineering (Mechanical , Electrical, Plumbing) teams. Depending on the project scope, the building design team will also include other professional services such as Structural & Geotechnical Engineers, Civil Engineers, Controls Integrators, Security and IT Integrators, Fire Code & Safety Consultants, Extraction Specialists and Consultants, cGMP (Pharmaceutical Manufacturing) Consultants, and more.

Through team meetings and direct coordination, we assist in guiding each discipline through the portions of work that touch and involve the Horticultural Program. We review their work at critical milestones, evaluate tradeoffs and present them to ownership groups where decisions are required.

Circulation of staff and the function of support rooms are important to a smooth running facility. (No, the janitor closet cannot turn into a flower room)

Specification of Horticultural Equipment - Early in the Design Phase

We specify in the exact horticultural equipment that matches the facility goals early in the design phase to ensure everything fits and functions well. These systems include:

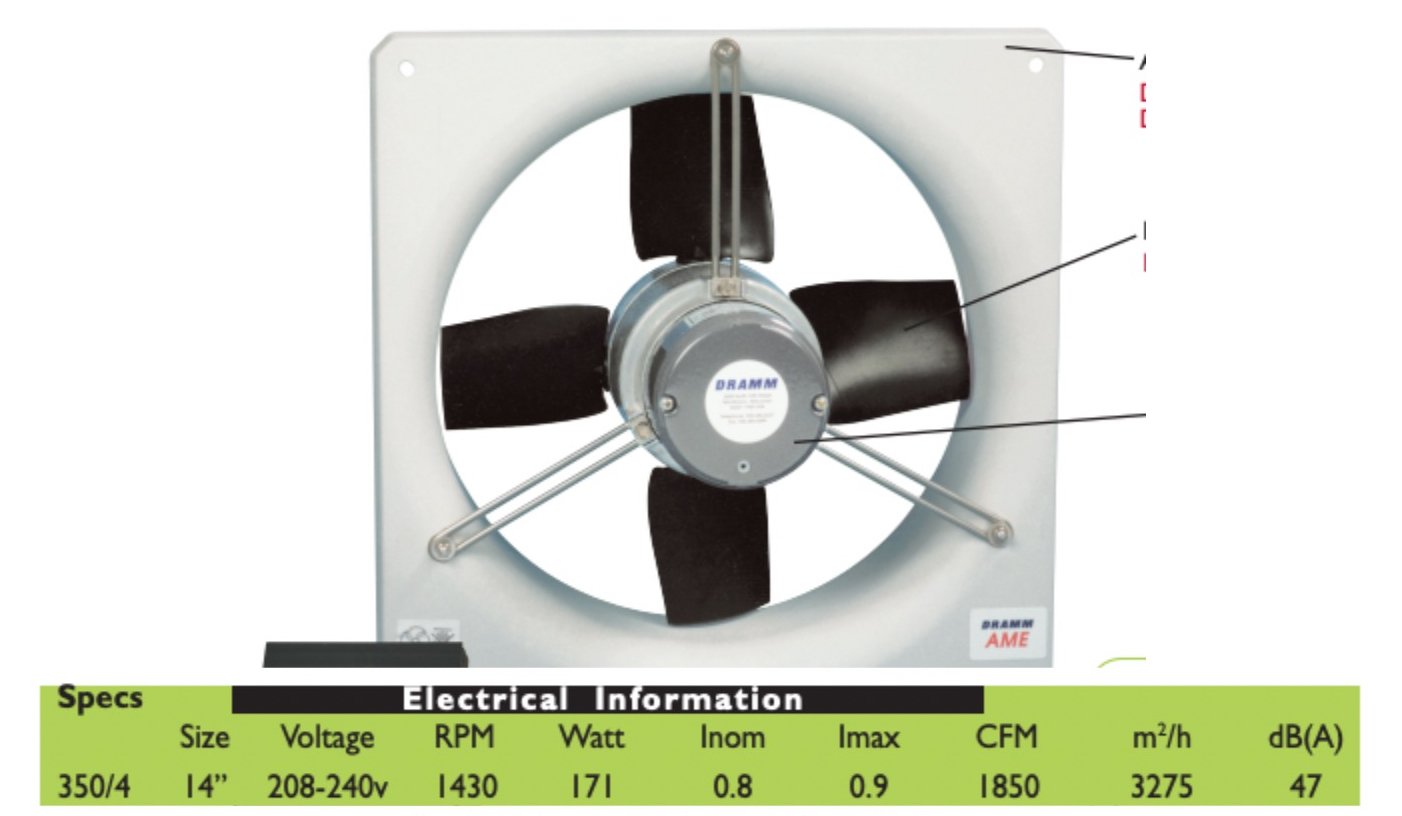

Horticulture Process HVAC and Airflow - Performance Criteria, System Evaluation, Airflow Strategy for optimal plant health

Lighting - Luminaire Style, Partner ‘Shortlist’ and Evaluation, Lighting Layout

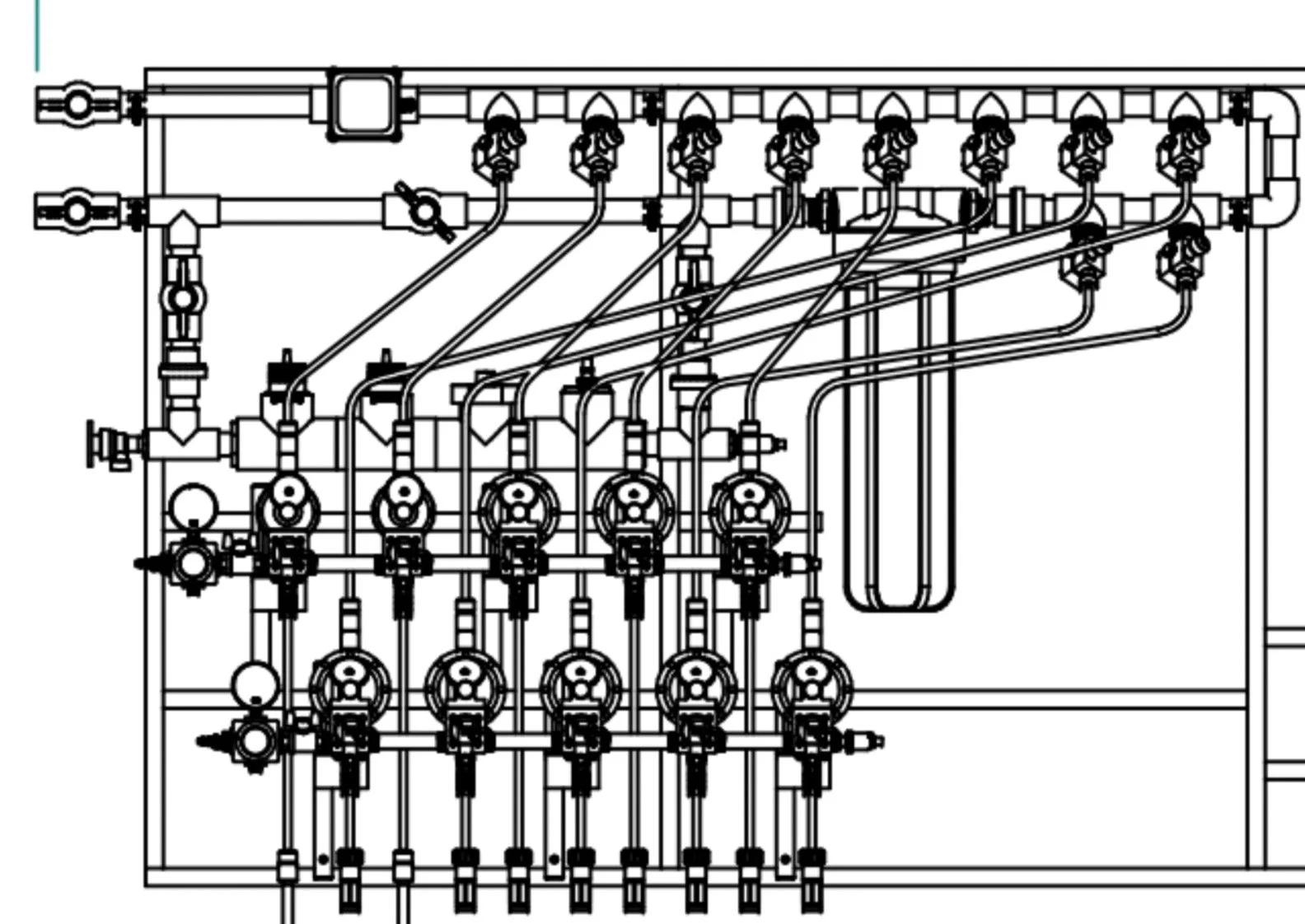

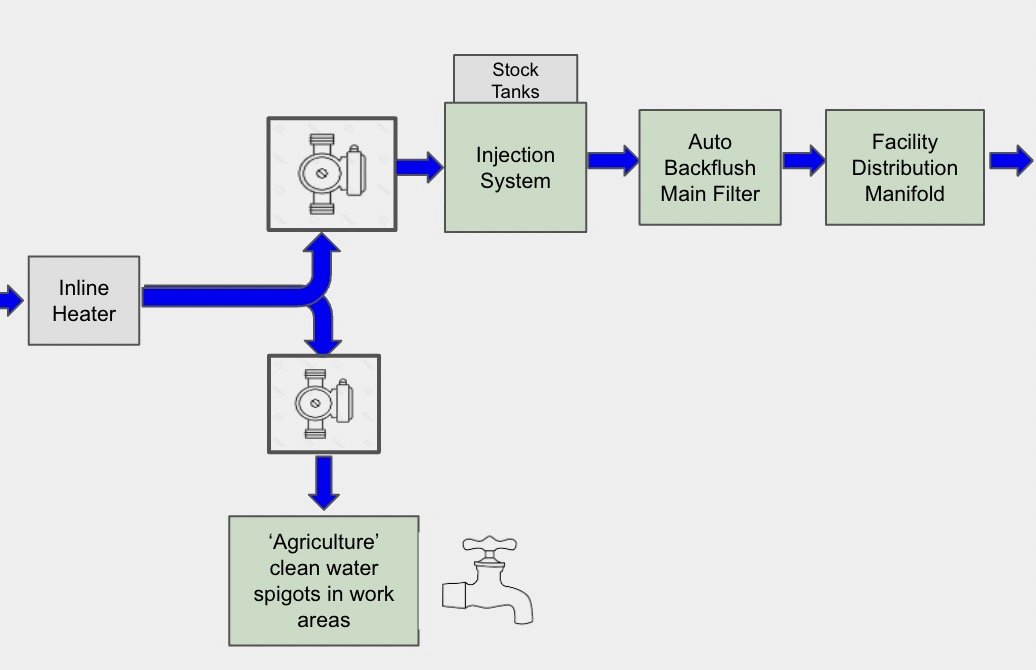

Fertigation + Process Water Treatment - From the water source coming into the building to the roots

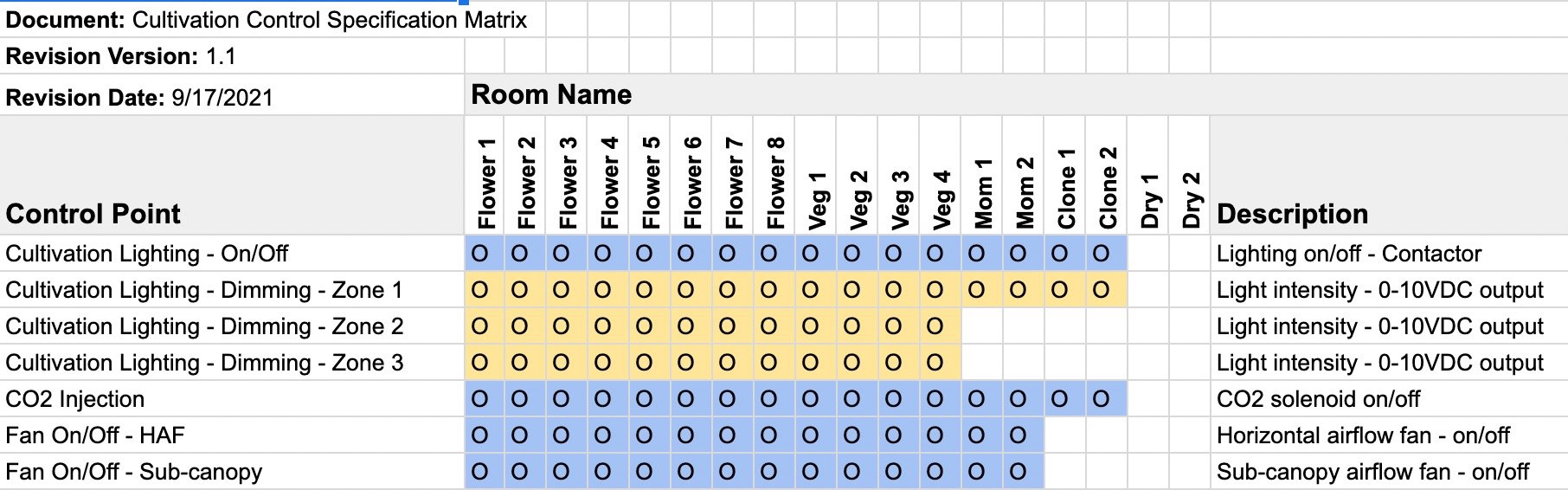

Horticultural Control Systems - Design and specification of horticultural control system, integration into the building management system (BMS), as well as assistance in partner selection (e.g. Argus, Priva, Agrowtek, Total Grow Control, GrowLink - or your preferred vendor)

Benching/Racking + Room Clearances for worker and material movement'

Horticulture Work Areas - Wet benches, Quarantine Rooms, R&D Spaces as needed throughout

Design to Horticultural Regulations - for example, in a 25B regulated jurisdiction, setting up the operation to best comply with zero pesticide use through facility design

In-rack airflow for vertical setups

HE Anderson positive displacement pump injection system

Block digram portion of a precision ag fertigation system

I/O points for the horticultural portion of a control system - connected with the BMS (Building Management System)

Startup Phase: Opening Narrative, System Commissioning and Horticultural Tuning

As the facility nears completion and aims to begin operations, we assist by consulting regarding the facility startup and operation initiation. This includes scheduling time before the plants move in to commission the systems: test that they work as intended and fix problems before they impact high value crop

Plants move into the building, we set up our in-house sensor system to help fine-tune the horticultural systems - controls setpoints, water temps, DO levels, EC setpoints, fan directions and speed, HVAC damper settings, zone timing and waterings, flush timing and more - details matter, and there are a lot of them to adjust on a new highly integrated system.

Ongoing Support and Expansion

After the facility has reached a steady state of production, we help producers reach the next level. Through experimental design, data gathering, analysis and recommendations we help drive continuous improvement. With knowledge of the facility and horticultural process we are well equipped to suggest changes to the production system to meet changing needs and market conditions.